You take care of the structure of your control cabinet and use various terminal blocks to organize your electrical installation. If you are still missing protective conductor terminals to complete your system, then you have come to the right place in this catalog from our shop. Here you can get all common variants from well-known manufacturers at top conditions. Protective earth terminals belong to the series terminals and were developed for electrical distribution installation. These are capable of accommodating fine-wire, multi-wire or solid conductor cross-sections. Cables with attached ferrules can also be installed in protective conductor terminals.

What is a protective conductor?

The protective conductor or PE conductor (PE stands for protective earth) is primarily used to connect the masses of electrical devices and conductive elements to earth. The protective conductor is easily recognizable by its green-yellow color.

Already knew

The nationwide establishment of the protective conductor in Germany, Austria and Switzerland took several decades. More than 50 years passed from the first proposal to introduce a 'neutral conductor' around 1914 to the uniform definition of the green and yellow marking in 1965.

An example: Let's take the classic NYM-J 3x1.5 mm² sheathed cable. Two wires carry current here, the one with the blue insulation and the one with the brown insulation. The third wire is the green-yellow protective conductor, which normally does not carry any current. If a current-carrying phase touches a metallic housing, a so-called residual current flows through it. If there is no protective conductor, the housing is not grounded and the residual current cannot flow. If a person touches the housing, the current is returned to earth via their body. This not only results in an unpleasant discharge, but in some cases leads to burns or, in extreme cases, to an electric shock, which can lead to cardiac arrest. However, if a protective conductor is properly installed, the enclosure is connected to earth through it. The residual current can thus flow off via the protective conductor.

In the control cabinet, the incoming protective conductors are sorted and fastened via protective conductor terminals.

What is a terminal block or a feed-through terminal block for protective conductors?

Terminal blocks fulfill several functions and are among the most important components within a control cabinet. It is mounted on the DIN rail. In general, terminal blocks are connecting elements between the incoming cables and lines of an installation and the actual control cabinet installation. Technically, the special protective conductor clamps do not differ from the clamps for external conductors or neutral conductors, but they are specially designed to accommodate the green-yellow protective conductor.

TIP

Many ground terminals also have a coloured, mostly green-yellow housing. Their purpose is therefore unmistakable and the terminals in the control cabinet can be recognized as such at first glance.

Feed-through terminals are also often mentioned. 'Terminal block' is a generic term that also includes other types of terminals. These include, for example, fuse terminals and relay terminals. Other terms describe the way a terminal is constructed or its ability to connect the conductors. In this context one often hears about one-tier terminals, three-tier terminals, spring-loaded terminals, push-in terminals or screw terminals.

Why should I use protective conductor terminals?

Feed-through terminals for protective conductors are required connecting elements in the control cabinet between the rigid incoming cables or lines and the following control cabinet installation. These offer the necessary flexibility to connect the protective conductors to the end devices easily and clearly. A clear installation would not be possible without the feed-through terminals. In practice, the incoming cables and lines are clearly laid out on the terminals and the individual wires then lead from there to the devices in the control cabinet. This keeps the entire installation flexible. There are connection points and nodes for checking and changing the system structure.

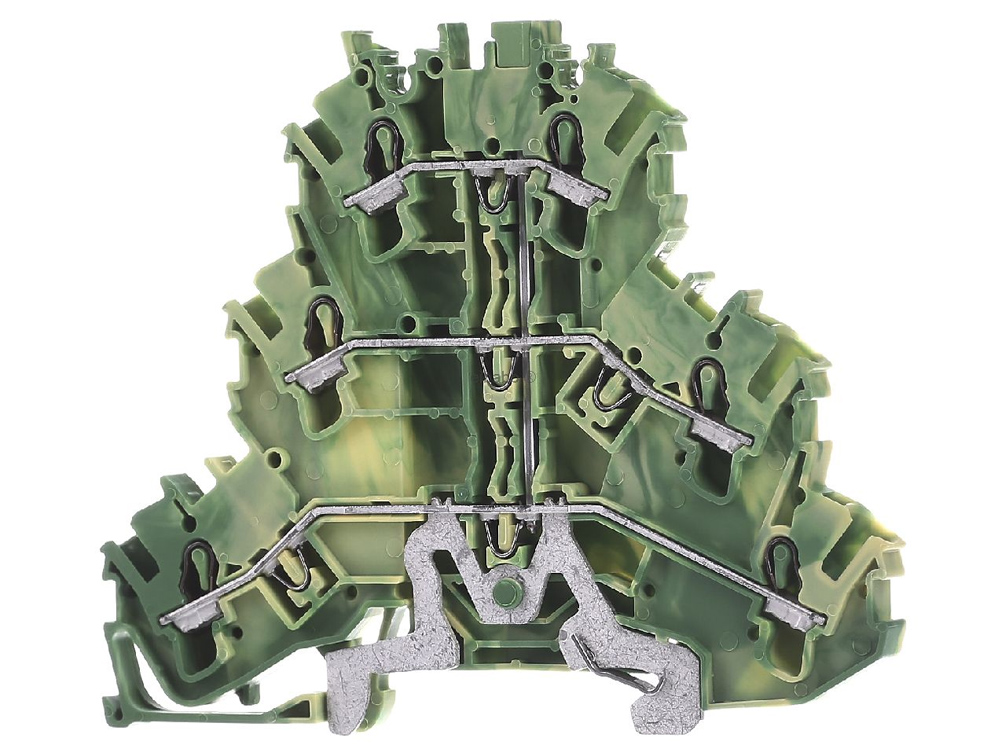

Image: WAGO 2002-3207 three-level terminal

Image: WAGO 2002-3207 three-level terminal

Each protective conductor connection that is made assumes a protective function specified in the circuit diagram. This means that both the installation of the system and the function of individual connections are always traceable. This makes later maintenance, additions or repairs easier. Changes are possible at any time by reconnecting individual lines. The rigid supply lines remain unaffected.

What is the difference between protective conductor terminals?

Each manufacturer builds the protective conductor terminals slightly differently. However, the principle is the same. There are single-level clamps and multi-level clamps. While you can only connect one protective wire in the single-level terminal, several incoming and outgoing lines can be installed in multi-level terminals. A multi-level arrangement saves an enormous amount of space in the control cabinet.

Another distinguishing feature is the way the wires are attached. With a screw terminal, the respective wire is fixed with a screw connection. This method is comparatively complex and takes a lot of time. Especially when the system is complex, you save a lot of time by using a spring-loaded terminal. This variant makes the electrical contact using a spring. The spring usually consists of a bent, flat copper contact. The protective conductor must be inserted through a hole in the copper contact. This is only possible if the contact is clamped with a pointed tool. When the clamping tool is removed, the spring pulls back and the protective conductor is jammed. This connection is released in the same way. Push-in mounting is another connection variant. This is similar to the spring-loaded terminal. But unlike the spring-loaded connection, installation is tool-free and therefore even faster. The protective conductor is inserted into the spring shaft of the terminal and the spring locks automatically. You need a tool to loosen the connection. Bend the retaining spring to the side with a small screwdriver and the protective conductor can be loosened. This method saves a lot of time, especially for cores with solid conductors. The use of ferrules is recommended for cores with flexible conductors (strands). Fastening the conductors using insulation displacement terminals is rather rare. Use this variant if your conductors are particularly thin. Here, the contact is made through a small cut in the insulation.

Cheaper in a set

Protective conductor terminal blocks are available individually or in sets of 25, 40 or 50 at an attractive price advantage.

The cross-section of the protective conductor also affects the protective conductor terminal. Here in the shop you can get the right protective conductor terminals for all common cable cross-sections. Whether a clamp can be used for a specific cross-section is usually stated on the clamp.

Why are protective conductor terminals not closed on one side?

The space in a control cabinet is almost always tight. The storage capacity of a control cabinet is generally specified in module widths (HP). Protective conductor terminals are not manufactured according to this grid dimension, but as narrow as possible. The width is determined by the design of the electrical connection and the cable cross-section. Since the terminals are mounted directly in line, there is no risk of touching the contacts on the open sides. Without the second side cover, a terminal is slightly narrower. A cover is only attached to the last terminal in a row. The narrower the individual terminal is, the more terminals can be accommodated on a specific section of the DIN rail.

You can buy protective conductor terminals quickly and cheaply in the eibabo® technology store – your competence center for smart homes and electrical installations. We offer branded products from ABB, Dehn, Hager, Phoenix, Pollmann, Schneider Electric, Siemens, WAGO, Weidmüller, Wieland in large quantities. We deliver our range worldwide.

![]()

Catalogue content:

In this eibabo® catalogue Terminal blocks > Ground terminal block you will find items from the following product groups:

Item overview:

- Actuator terminal

- Base clamps

- Built-in housing

- Cage clamp

- Connection technology

- Feed terminal

- Feed-through terminal block

- Four-level clamp

- Ground rail

- Ground terminal

- Ground wire disconnect terminal

- Information technology

- Initiator terminal

- Installation clamp

- Installation clamps

- Multi-level clamp

- Protective conductor

- Shield connection technology

- Single clamp

- Spring clamps

- Spring clip

- Terminal blocks

- Terminal strip

- Test disconnect terminals

- Three-wire terminal

- Through terminal

- Twin clamp

- Universal clamp

from the following manufacturers:

Manufacturer overview catalogue Protective conductor terminal:

- ABB

- Dehn

- Hager

- Phoenix

- Pollmann

- Schneider Electric

- Siemens

- WAGO

- Weidmüller

- Wieland